About

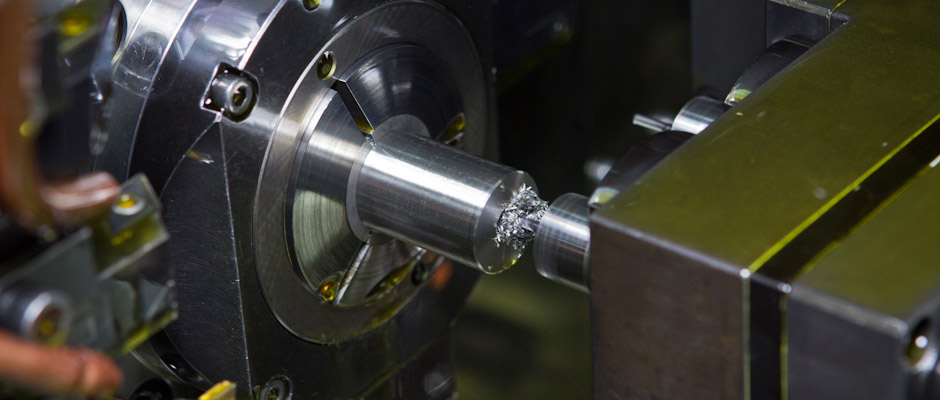

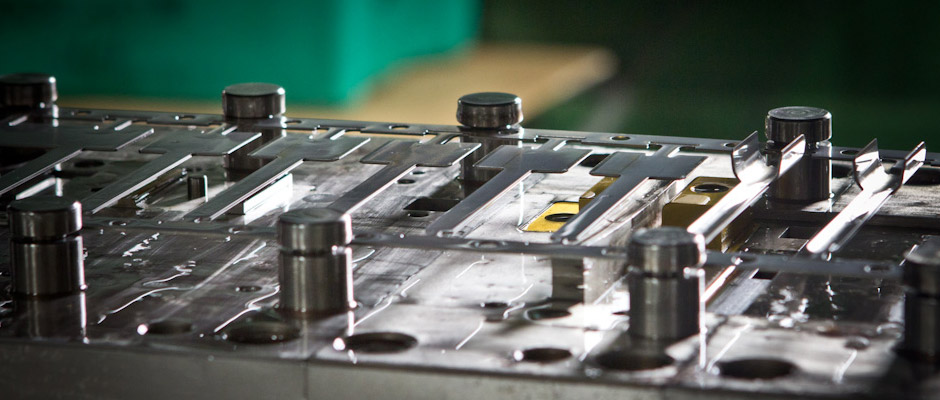

Preferred Tool and Die is a manufacturing company obsessed with giving customers the highest quality stamped and machined components and subassemblies. With over forty years of industry experience, two high-tech facilities, and fifty thousand square feet of manufacturing floor space, Preferred Tool and Die is capable of exceeding customer expectations.

Preferred Tool and Die was founded over forty years ago with the belief that a customer’s needs are the most important part of the manufacturing process. Through our experience working with clients, we realized we could save our customers time and money by being involved early on in the product development cycle. Since then, Preferred has brought this mindset to its growing offerings of products in an array of industries. Because of our attention to customer needs, we have grown from a small company providing progressive tooling into one of America’s leading providers of in-house engineering, tool-building, production stamping, and precision machining services.

Preferred Tool and Die’s customer-focused organizational structure gives us the ability to meet changing customer needs and evolving industry conditions. Our fully-integrated divisions work together to bring you innovative first-class parts at competitive pricing so you can compete in a global market.

Everything begins with the culture set by the owners. Our executives take an active part in day-to-day management, ensuring our customers receive the benefit of cutting-edge technology, strong organizational structures, and sustainable growth practices. Their commitment to giving employees an organizational structure to excel, while generously giving back to the community, creates an environment which emphasizes quality and service.

Our experienced management team brings their expertise in manufacturing, project management, and client communication to the creation process. Our customer-driven approach is based on our extensive background working with clients to produce progressive tools, in-house engineering services, and production stamping.

Many projects begin with our engineering and development team working with a customer to create viable prototypes. We use the latest technology and software to streamline the creative process and minimize costs while speeding up component availability.

Once an item is in production, our project managers guide the process, ensuring that specifications are met at every step. As a registered ISO 13485 and ISO 9001 certified company, quality assurance is a top priority and nothing leaves our facility without flowing through our QA guidelines.

We have been manufacturing components for national and international companies in the medical, scientific, aerospace, and high-tech industries for decades. Our highly skilled and dedicated staff stand ready to meet your needs, whatever your project requires.