Connection Housing / Material: Stainless Steel

Problem: Local Injection mold company needs consistent quality leaf springs it assembles into component for their customer’s centrifuge. Current vendor’s process does not yield leaf springs with critical spring load dimension in spec.

Solution: Preferred’s team representing Quality, Sales, Engineering and Tooling meet with both the injection mold company and the centrifuge manufacturer to get to the heart of the problem. It was discovered that the current vendor was using narrow gauge strip run on a 4-slide machine to process this part. Preferred proposed a small progressive die utilizing wider strip stock to minimize the effect coil set would have on the critical dimension. Also, the repeatability of parts produced from the progressive tool would be far greater than the previous method due to the construction quality of the tooling.

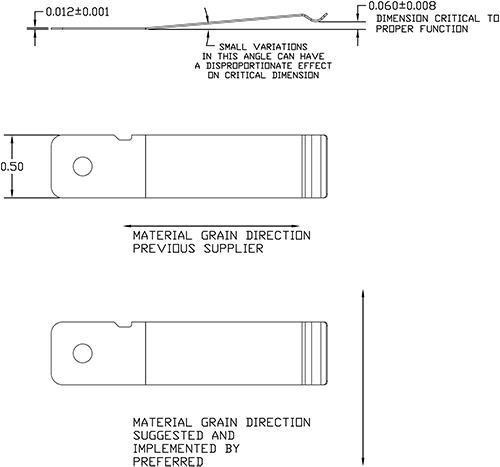

As you can see in the drawing below, the critical functional dimension is at the end of a relatively long arm. Small variations in how the part is struck with the bend tooling can yield parts that will be out of spec. Effective tolerance on this bend angle is less than +/- 1 degree! This type of quality can only be achieved by using the best tooling and equipment available.

Summary: Most companies will not pay to re-tool for a component. Preferred’s customer invested in re-tooling for the leaf spring due to our track record working with thin gage stainless steel and our outstanding quality system.

Preferred’s In-House tool design team utilizing a customized version of AutoCad that is geared toward speed, efficiency and accuracy, addresses all capability issues with current process and delivers an efficient, robust tool design that will deliver consistent quality over the life of the project.

Preferred’s tool building team fabricates all custom components needed using our full service tool room, utilizing Wire EDM, CNC machining centers and Moore Jig Grinders.

Our production department, working with Quality Assurance, delivers a first article inspection report along with samples that are in spec and on time. Delivery was especially critical on this project due to the quality problem with the current vendor.